Why Your Inventory Rules Are More Important Than Ever

Fulfillment must get smarter to move your product. Brands have been relying on their 3PL systems for this, but why outsource the oversight and...

Influencers, wholesale & more

Inventory effective & expiration datesNo more spreadsheets required

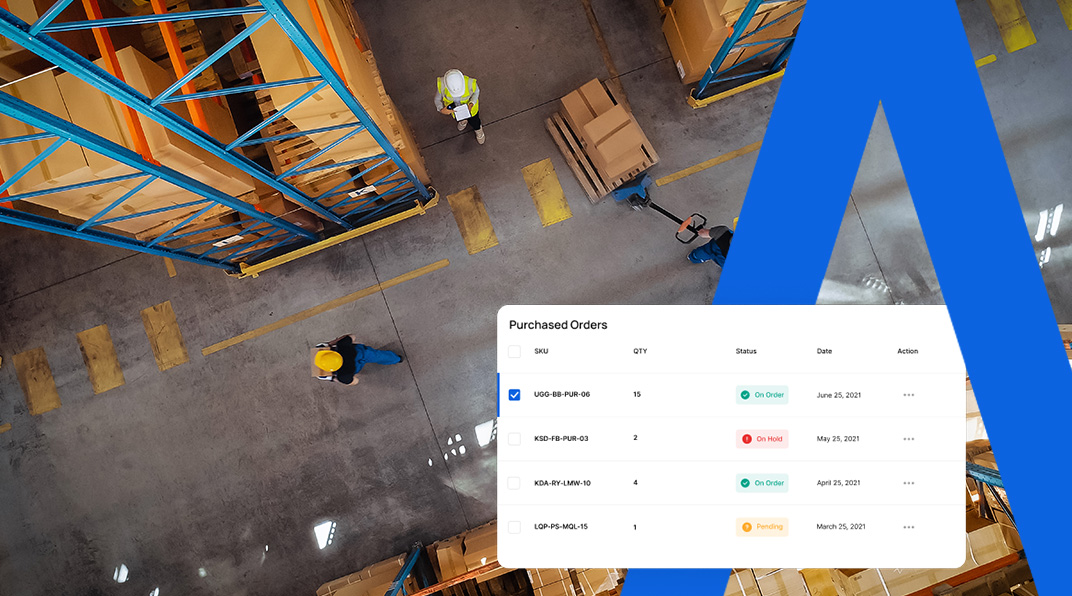

Multi-status, multi-location inventoryWarehouses, stores, and channels

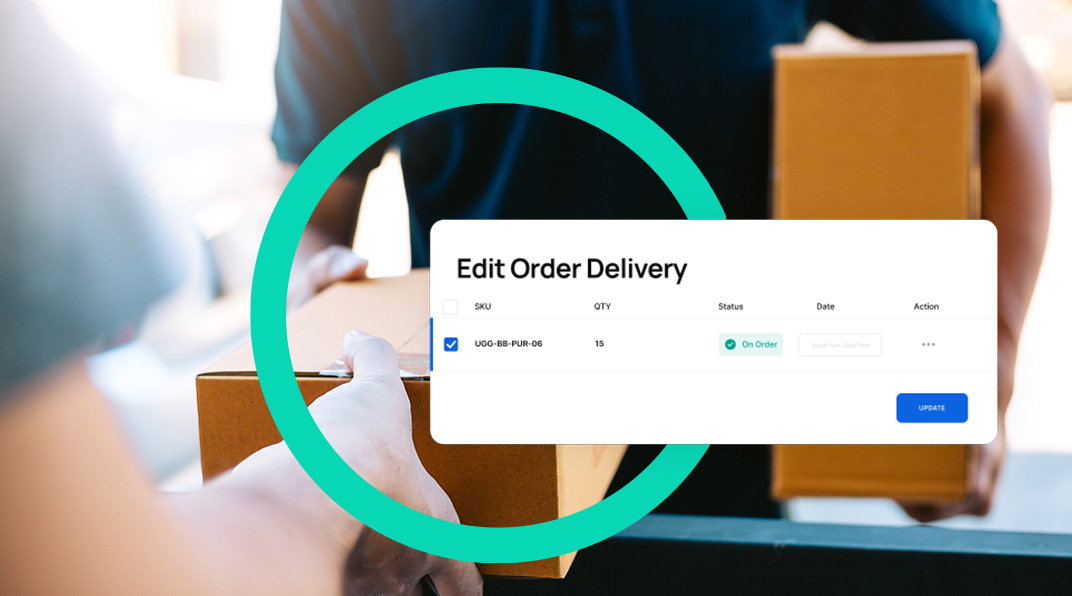

Fulfillment holds & order editsAuto-hold on new CX ticket

Automate fulfillment rulesBundles, marketing SKUs, and more

Influencers, wholesale & more

Inventory effective & expiration datesNo more spreadsheets required

Multi-status, multi-location inventoryWarehouses, stores, and channels

Fulfillment holds & order editsAuto-hold on new CX ticket

Automate fulfillment rulesBundles, marketing SKUs, and more

3PL partners are the secret to successful growth and scale. DTC brands should choose a network that boasts multiple warehouses instead of a single large one.

According to a 2021 report conducted by Retail Industry Leaders Association (RILA) and McKinsey, over 90% of consumers consider two- to three-day shipping as the baseline for meeting expectations. A staggering 30% view same-day delivery as the standard. Meanwhile, six out of ten consumers claim they would be “unlikely” to purchase from a retailer again if an order didn’t arrive during the expected delivery window.

It’s clear that since the term ‘Amazon effect’ was coined, customer expectations for rapid delivery times (and accurate delivery estimates) will only continue to increase. Rather than be the underdog, big-box players like Walmart are responding to demand by leveraging the power of their own massive logistics network , setting new benchmarks and becoming true competitors of the e-commerce giant.

DTC e-commerce brands will lose customers if they fail to offer fast delivery, no matter how incredible the product. Consider this: Same-day delivery is so anticipated that 61% of consumers are willing to pay for it.

This is why your 3PL network is so important. Partnering with a logistics provider that offers a nationwide warehouse network brings brands more flexibility and responsiveness in a landscape where speed is the name of the game.

Here’s why you should be leveraging a multitude of strategic warehouse locations, as opposed to having all your inventory sitting in one giant warehouse:

Location, location, location. A swimwear company with its warehouse located solely in California is potentially alienating new customers in other regions. You may be where your more frequent customers are, but as soon as the summer rush for swimwear hits the East Coast, those bathing suits are going to take a lot longer to ship. Why would someone who doesn’t already know your brand and love the quality of your product wait seven business days for an item when your competitor can have something on their doorstep within two?

Strategic placement of several, smaller warehouses will shorten your delivery timeframe to your key consumer hubs, especially during seasonal and peak times when your buyer demographic may change and you need to make a favorable impression on first-time customers who have discovered you in their gift shopping journeys.

The further away your customer is from your fulfillment center, the longer and more expensive their order is to ship. When parcels don’t have to cross as many shipping zones, it lowers your overall shipping costs. Simple!

More warehousing facilities equals more square footage to store inventory reading for picking and packing. It’s harder for your business to handle higher order volumes during peak season with just one warehouse, as you can easily end up with large backlogs in order processing and picking. Moreover, in the event of major disruption to fulfillment and shipping (e.g., COVID-19), you will need more space to hold overstock, unsold inventory, or packages that need to be rerouted.

It’s simple: Shorter trips reduce emissions. You can also reduce packaging waste by combining multiple items into one package and streamlining materials, which you can action across multiple warehouses.

As we discussed earlier, customer satisfaction relies heavily on fast, painless delivery. A healthy warehouse network helps brands to avoid stock-outs by rerouting orders, another huge win for online shoppers. It’s worth remembering that when consumers can’t find the precise product they’re looking for, nearly a third will buy the item elsewhere.

By having a bunch of smaller warehouses housing different types of inventory, you can avoid those dreaded ‘out of stock’ signs and keep customers smiling. Satisfied customers improve your coveted net promoter score (NPS), so it’s a double win.

Ryder Ecommerce by Whiplash , a nationwide omnichannel fulfillment provider, makes this flexibility and responsiveness a reality with a warehouse network that delivers to 99.9% of the US within two days.

“Faster turnaround has enabled us to scale up how many orders we can ship per day,” said Jon-Mark Craddock, Director of Logistics at Tuckernuck. “Our biggest day so far with Whiplash saw us ship between 19,000 to 20,000 orders during our January sample sale—a volume that would have taken around 14 days with our old 3PL.”

With ChannelApe’s Distributed Order Management (DOM), brands can rest assured that orders will be fulfilled from the most efficient warehouse location, regardless of customer location. Whiplash’s 18 strategically located facilities—offering 6.5 million square feet of space—are the perfect complement to delivering agile and accurate shipping fulfillment services at every point of the supply chain.

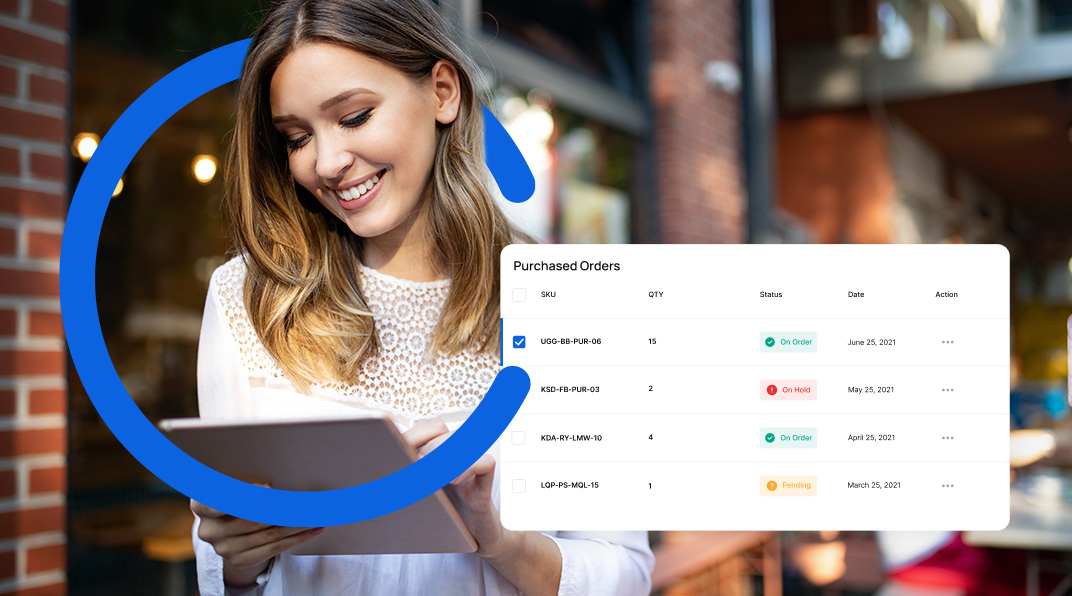

By connecting Whiplash’s scalable fulfillment platform with ChannelApe’s real-time inventory and order management capabilities, merchants gain access to an intuitive, all-in-one dashboard that gives them unparalleled visibility over their fulfillment operation. From rules-based order routing and packing to custom, value-added fulfillment services, Whiplash + ChannelApe is a gateway to streamlined, down-to-the-minute fulfillment for higher conversion rates and happier customers.

Fulfillment must get smarter to move your product. Brands have been relying on their 3PL systems for this, but why outsource the oversight and...

ChannelApe and its best-in-class warehouse partners in both Canada and Mexico have coordinated and streamlined all the processes, so you can launch a...

Discover how Shopify 3PL integration apps go beyond just connecting the dots.