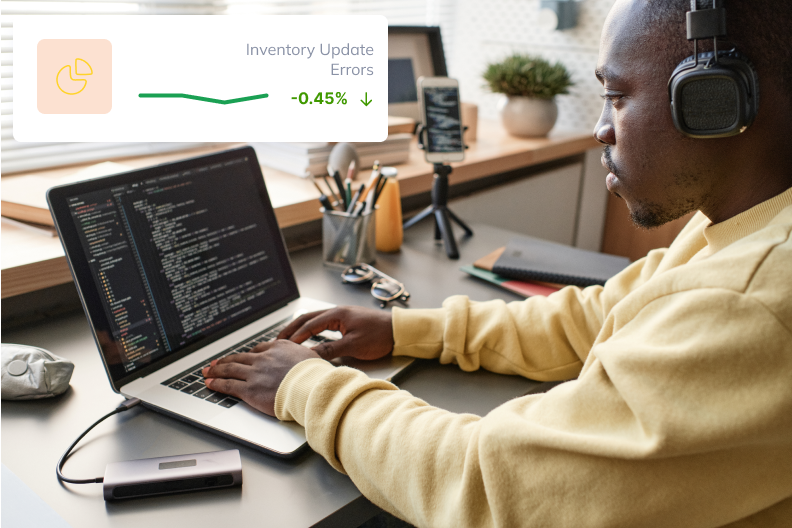

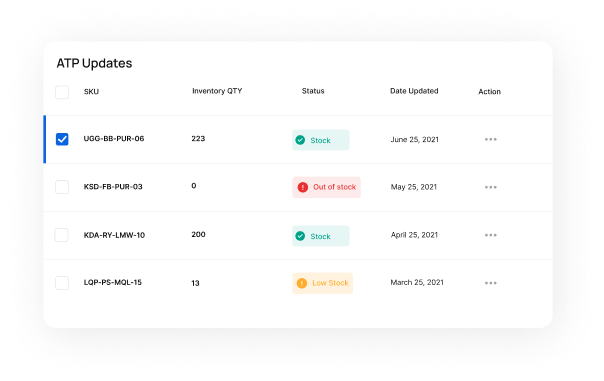

Never manually update inventory again.

Your inventory comes from multiple places (manufacturer, warehouse, returns) in multiple statuses (on hand, on order, committed, reserved, damaged, and more)... imagine what you could accomplish if you were able to ditch the spreadsheets?

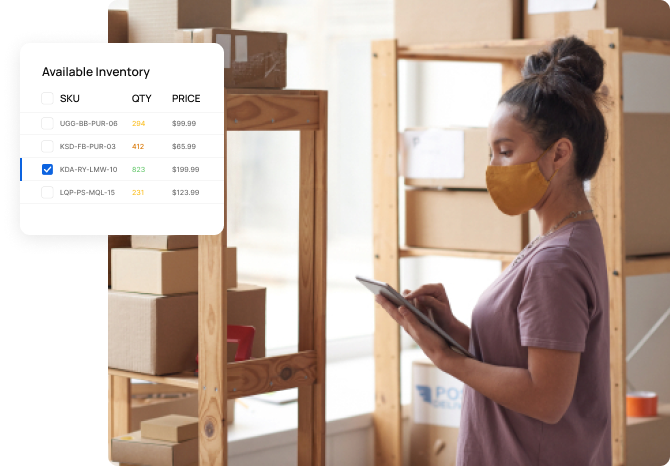

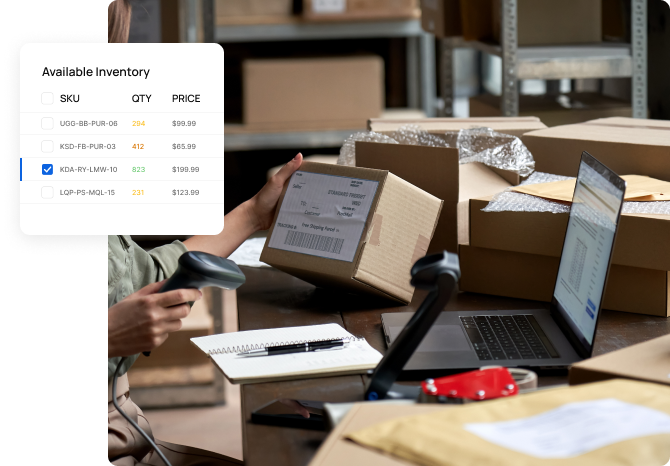

Reduce unplanned backorders and overselling.

When inventory data is in sync across your sales channels, warehouse(s), external partners, and ERPs, you can rest assured that you’ll never run out of what you need.

Make data-driven decisions based on the realities of your brand.

Mitigate the risk of overbuying, ensure everything at your warehouse is for sale on your site, or even start pre-selling—all because you can leverage timely, accurate data.

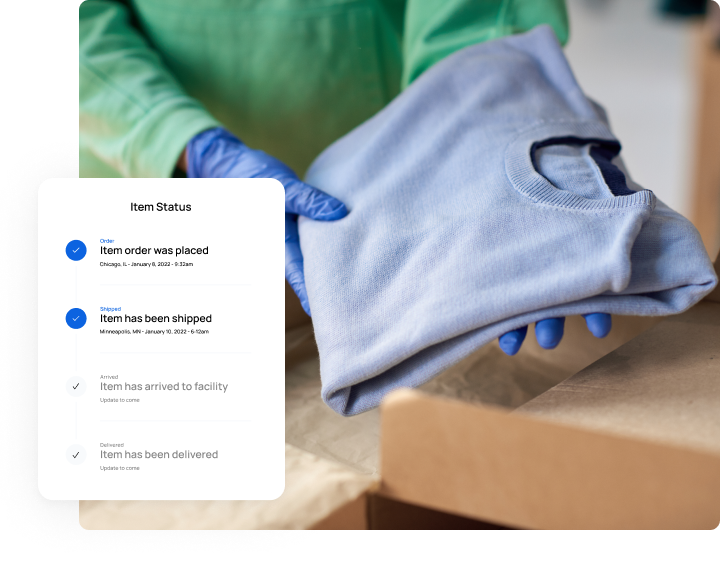

Know why your stock levels are the way they are.

When you can rely on a single source of truth for all things inventory, you can rely on full traceability to make sure no opportunity goes unrealized (e.g., new sales order, manual adjustment by the ecomm team, etc.).

Get returned inventory back to sellable ASAP.

41% of customers order multiple products with the intent to return—having a central hub for inventory data means you’ll never have returned merchandise sitting idly at the warehouse ever again.