Ditch the CSV exports, spreadsheets & ERP nightmares.

We connect to all your sources & destinations of inventory, providing you a single mission control system for visibility and control that connects back to relevant systems. ERP is important for financial teams, and spreadsheets have their place, but neither is built for DTC ecommerce.

What does ChannelApe do?

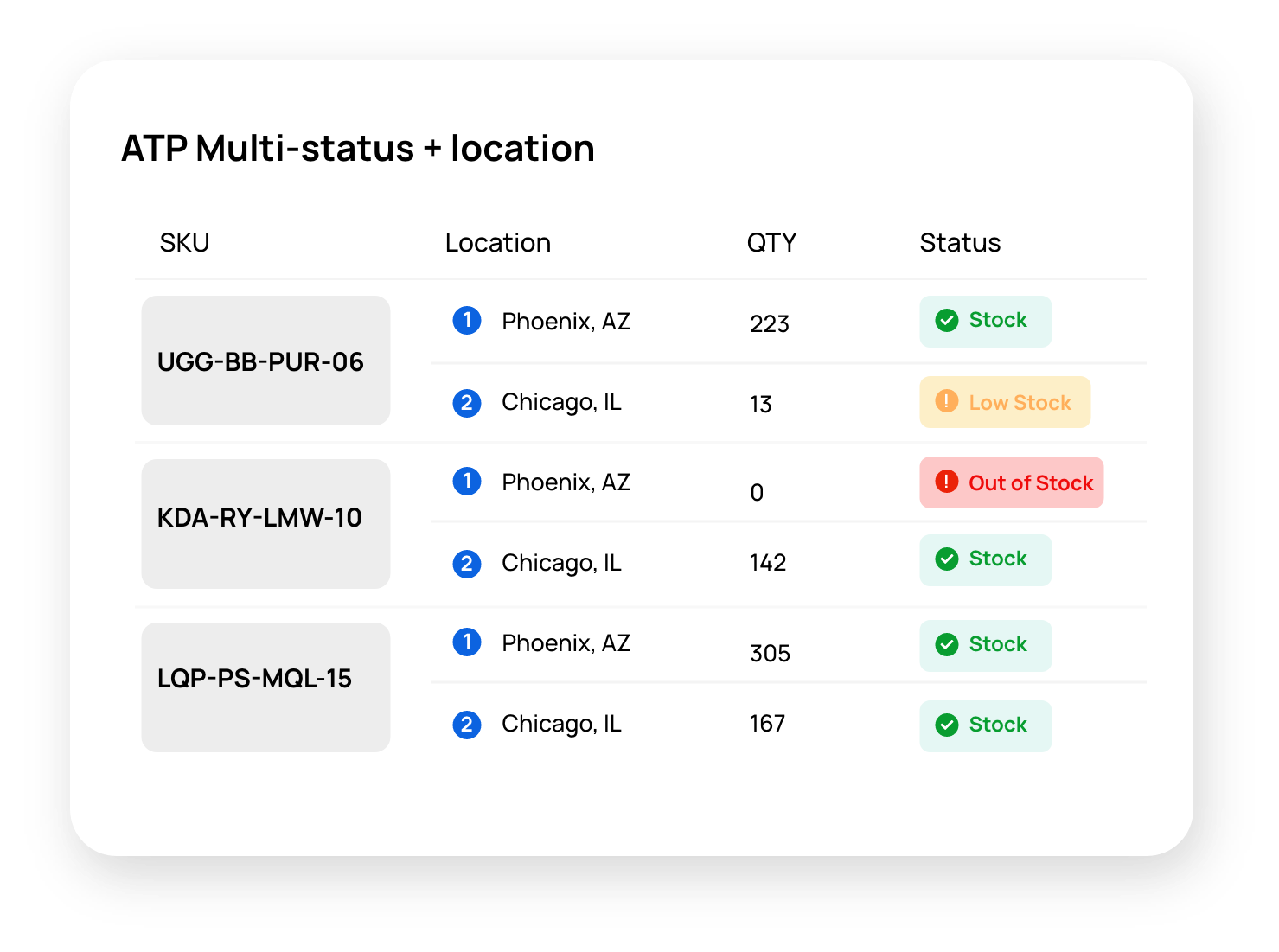

- Realtime, multi-location, multi-status, Available to Promise (ATP). No virtual location hacks needed here.

- Business Intelligence powered by Looker with prebuilt reports and the ability to build your own. Create your own dashboards, too.

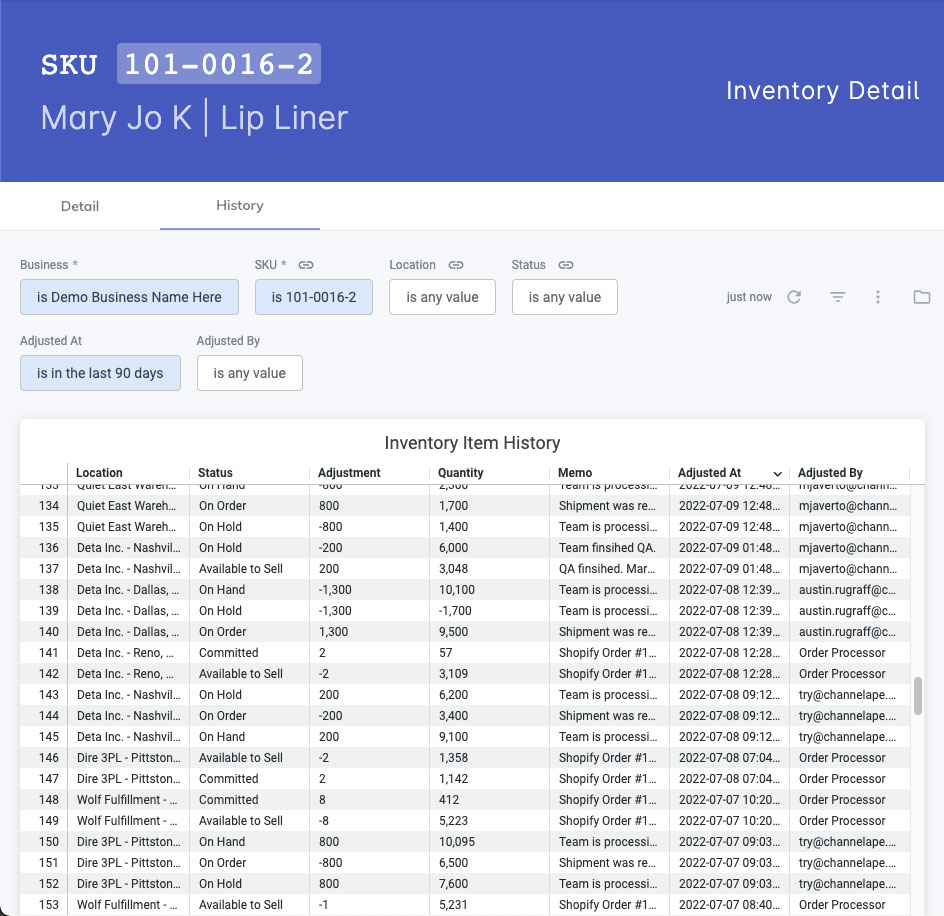

- Full history of every adjustment. Go back in time, see inventory at a specific point, find patterns, find exceptions & fix failures.

- Full traceability of every adjustment (e.g., new sales order, fulfillment, manual adjustment by ecomm team). Know WHY inventory levels are what they are.

Never manually update inventory again.

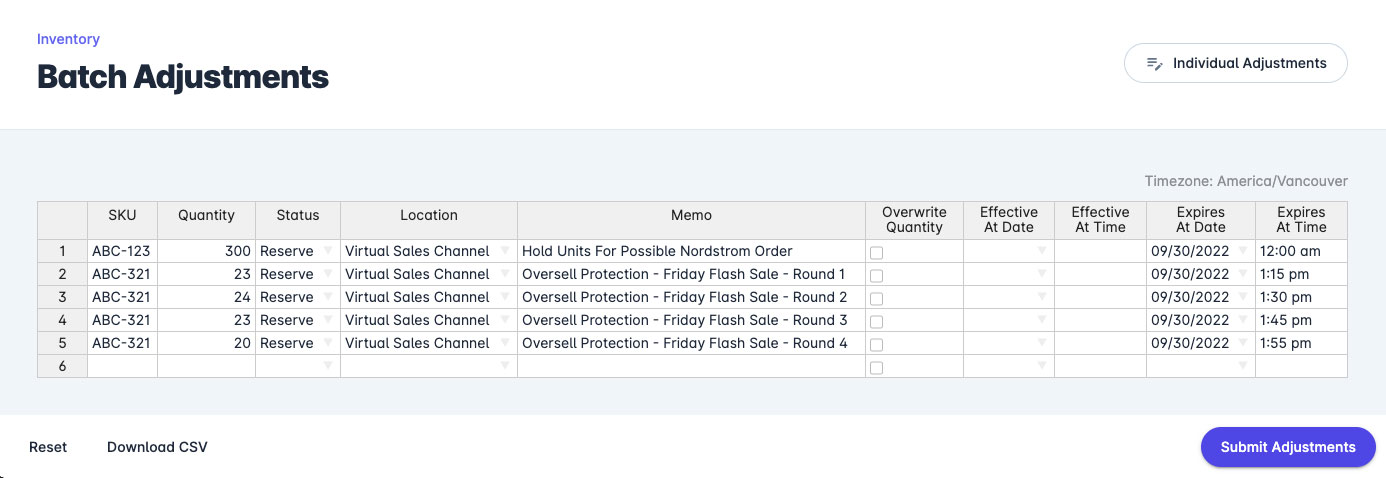

Want to presell a new product starting Friday at midnight, but want to plan and setup ahead of time so it "just works" at midnight? That’s how the largest brands on Shopify are utilizing ChannelApe right now!

Maybe you need to reserve inventory for an influencer or B2B order, but only until Friday by close of business? Then have it automatically go back your ecomm channel?

Or maybe you need to prevent overselling during that next flash sale?

What ChannelApe Offers

- Expiration & effective dates of adjustments allow you to plan for sales, protect inventory, and prevent upset customers.

- On Order & Reserve status to help you effectively control oversell situations (whether planned presales or preventing unwanted oversale).

- Ohh yeah, and this all syncs to Shopify and other sales channels, in real-time!

Get returned inventory back to sellable at the speed of light.

New finished goods, returns, and on hand levels, all in the relevant status in the same place, connected to warehouses, sales, and finance. Understand how much was returned and focus on getting it back to sellable ASAP.

- With our Loop Returns + Happy Returns integration, you'll be able to track returns inventory right along with new finished goods and what's on hand at the 3PL:

- Time of return request

- Each carrier scan event

- Delivery back to warehouse

- Return to stock

- Full traceability of every unit by status in the returns process next to your new finished goods inventory and your on hand inventory.

All your integrations, handled.

With support for all your current integrations, creating a unified view for inventory has never been easier.

Partners like:

- Sales Channels

- Fulfillment, 3PL, Returns

- ERP, Finance

Common Use Cases

Make every $ of CAC count

Keep NPS above 9 and get smarter with inventory reserves that expire, so you can make overselling a thing of the past. You can't afford to lose customers.

Sell before inventory hits the warehouse

And prevent the headache that comes after. Enter what is coming in, an effective date, and just "let it run" without any more effort.

Faster turns = better cashflow

Never let inventory get stuck in a "virtual location". Keep fulfillment partners honest based on returns monitoring. When visibility of all inventory is in one place, turns happen faster.

Save shipping $$ + CO2 emissions

It's impossible to fulfill from more than one location unless you have the right visibility into inventory. But shipping from Mexico to NYC and back for returns isn't really fair to mother earth.

Get easy access to your past data

With our industry leading Business Intelligence powered by Looker, you'll have easy access to slice and dice your data without an in house team and 6 figure budgets.

You can't improve what you don't measure

Our built in data lake and BI will give you the raw data you need to make better decisions.

No apps or syncing to think about

It "just works" without having to worry about how it'll sync. Want to "disable" a SKU or set of SKUs from updating? Easy, add a reserve or on order adjustment with expiration. Never forget to re-enable.

Release reserves of final units to limit overselling

Utilize our expiration and effective dates for adjustments to control the over-sell likelihood that leads to poor NPS.

Inventory is more than just quantity.

Gauge exactly how much you have left to promise customers with ATP inventory—knowing that inventory reserves for wholesale are removed from what is promised across all channels. Improve NPS and increase repeat purchases by preventing overselling and unplanned backorders. Proactively solve problems rather than react to them to keep customers happy and reduce CAC.

Features like:

- Real-Time Shopify Sync

- Multi-Status & Multi-Location

- Available-to-Promise (ATP) Inventory

Get the most out of your inventory

-

Overselling Impact

-

Customizable

-

Big Picture

See the big picture through data.

Putting all your data in one place is crucial to see the big picture. Virtual warehouse locations, virtual in transit locations, and confusing statuses don't help. We know this because we’ve solved this time and time again for the fastest growing Shopify businesses.

With our Business Intelligence powered by Looker, you'll get an enterprise-grade data lake, pre-built reports, and the ability to customize your own; directly out-of-the-box.

Need clarification?

Can this still update my ERP?

Yes! Our solution becomes the intra-day source of truth for inventory, the system you use to control inventory. While ERP becomes the inter-day source of truth for long term financial ledgers. ChannelApe is not a financial management system, it is a DTC Inventory and Order management solution that complements ERPs like Netsuite or SAP.

Can you connect to {x}?

As long as it isn't a fax machine or paper and pencil, yes. We've supported all types of warehouses with X12/AS2, SFTP/Flat File, REST/HTTP and SOAP/XML. The connection to the warehouse doesn't matter, that is the easy part. Same with ERP and Finance. We update ERPs after the movements for the day are over so it has a clean ledger which makes monthly closes faster, easier and more accurate.

What is ATP?

Available to Promise (ATP) is the uncommitted portion of a company’s inventory and planned production maintained in the master schedule to support customer-order promising. It allows a business to keep the minimum amount of a given product within their warehouses so that the use of the inventory space is efficient.